A Quick Overview of Jet Ski Pump Assemblies

Jet ski pump assemblies are among the more important parts of the jet ski, but what exactly do they do, and what are their different parts? Jet ski pumps are intricate systems that capitalize on water propulsion to keep your PWC moving. These components do a lot of work, so you need to have a good understanding of all that goes into these jet ski pump assemblies and how they work together. With the right understanding, you can better appreciate these pump assemblies and what they do for you and your jet ski.

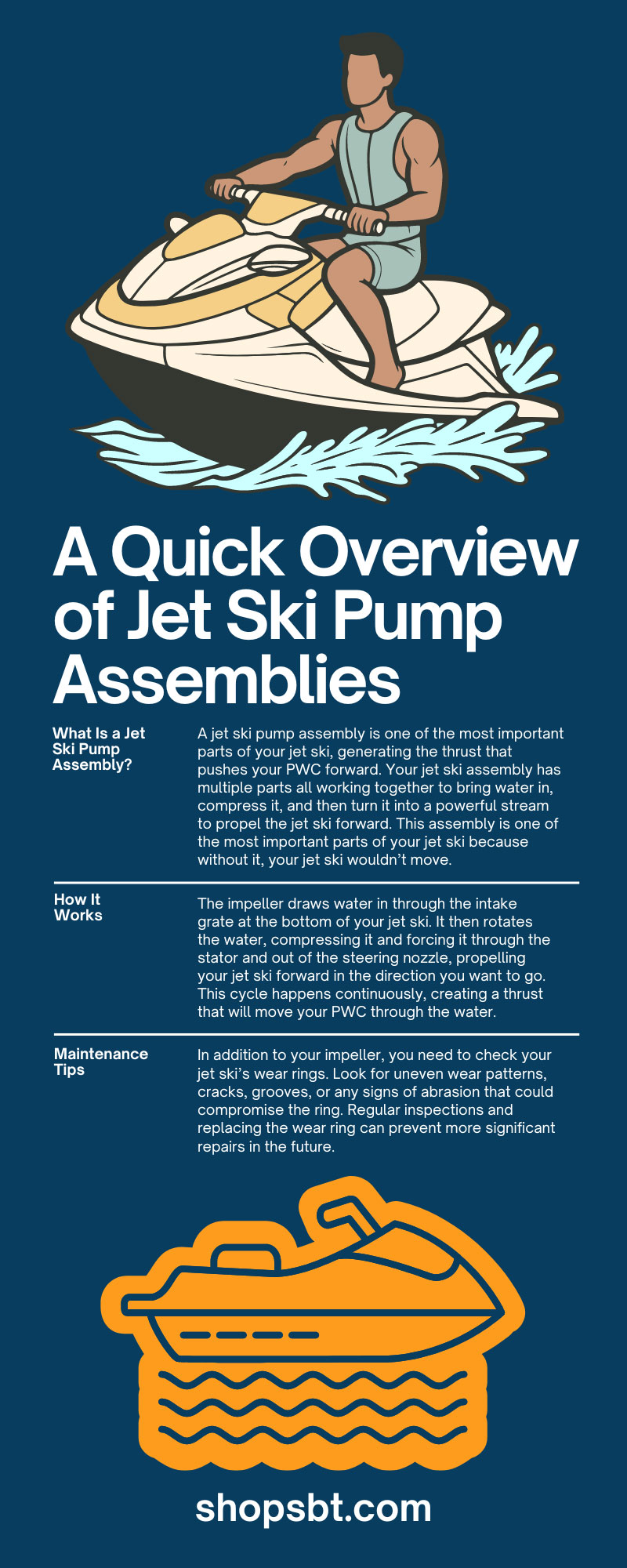

What Is a Jet Ski Pump Assembly?

A jet ski pump assembly is one of the most important parts of your jet ski, generating the thrust that pushes your PWC forward. Your jet ski assembly has multiple parts all working together to bring water in, compress it, and then turn it into a powerful stream to propel the jet ski forward. This assembly is one of the most important parts of your jet ski because without it, your jet ski wouldn’t move. A high-quality and efficient assembly will move your jet ski safely and efficiently across the water.

Key Components

As mentioned already, the jet ski assembly isn’t one component. It’s an assembly of different components all working together, including the following:

- Impeller

- Wear ring

- Stator

- Steering nozzle

Each of these parts plays a crucial role in creating and directing the water flow that moves your jet ski. If you want to be a responsible jet ski owner, you must know how each component works together.

Impeller

The impeller is one of the most important parts of the pump assembly. This component is a multi-blade propeller that rotates at high speeds, helping to draw in water that will generate thrust. This thrust is what moves your jet ski.

Most impellers use durable materials like stainless steel or aluminum, but you can customize them further with different shapes and sizes to meet your performance needs. The shape and size significantly impact the overall efficiency and power of the pump assembly, so you need to have a good understanding of your impeller.

Wear Ring

The impeller is an important component, but it’s not the only part of the pump assembly to stay on top of. The wear ring is a stationary ring that surrounds the impeller and creates a tight seal to prevent water from escaping. The wear ring also reduces cavitation, something that happens when air bubbles form on the surface of the impeller blades, hurting their ability to bring water in. Typical wear rings use high-strength plastic or stainless steel to withstand everything the water throws your way.

Stator

Another important part of the pump assembly is the stator, located between the impeller and the steering nozzle. The stator helps to direct and straighten the water flow for maximum thrust. It typically involves multiple curved vanes working together to guide the water in a specific direction, providing stability and control to the jet ski. The right high-quality stator will minimize turbulence and keep the water flowing smoothly in your pump assembly.

Steering Nozzle

The final component of the pump assembly is the steering nozzle. The steering nozzle is responsible for directing the water flow and determining the direction of the jet ski. When you turn your jet ski handles, you alter the angle of the steering nozzle to direct the flow of the water in the direction you’re trying to go.

How It Works

These are the key components of a jet ski assembly, but how do they actually work together? The impeller draws water in through the intake grate at the bottom of your jet ski. It then rotates the water, compressing it and forcing it through the stator and out of the steering nozzle, propelling your jet ski forward in the direction you want to go. This cycle happens continuously, creating a thrust that will move your PWC through the water. Manufacturers have also fine-tuned these assemblies so that you can still reach high speeds while maintaining control.

Unfortunately, since these parts of the pump assembly work together and have a great relationship, if something happens to any one piece, the whole system suffers. For example, any wear or damage on the impeller blades can lead to worse thrust. If you want everything to work as intended, you need to practice regular maintenance and replace worn-out parts sooner rather than later.

Maintenance Tips

Proper maintenance is essential for keeping your jet ski pump assembly in top condition. If you want to ride efficiently and stay safe on the water, maintenance for your jet ski and pump assembly is a must. Here are a few detailed tips to help you keep your pump performing at its best.

Regularly Inspect the Impeller

Carefully examine the blades of your impeller for any warning signs, like:

- Chipping

- Cracking

- Warping

Remember that even minor imperfections can affect overall performance, leading to reduced power and increased fuel consumption on the water.

Check Your Wear Rings

In addition to your impeller, you need to check your jet ski’s wear rings. Look for uneven wear patterns, cracks, grooves, or any signs of abrasion that could compromise the ring. Regular inspections and replacing the wear ring can prevent more significant repairs in the future.

Clean Your Stator

If you want efficient riding on the water, you need to clean your stator of any leaves, sand, or other blocks. A great solution is to regularly flush your stator with fresh water or use a fine mesh screen or filter to prevent debris from entering in the first place.

Check Your Steering Nozzle

Be sure to also check your steering nozzle regularly. Look for fractures or deformations that could get in the way of proper steering. When you check these issues and address them promptly, you can keep your jet ski stable on the water.

This quick overview should help you understand the different components and functions of jet ski pump assemblies and how to maintain them. Taking care of your pump assembly can be difficult, but with the right knowledge and jet ski pump parts from SBT, it can be easy. Now, you can give your pump assembly the maintenance and care it needs!

No Comments Yet